top mechanical engineering college in Punjab

Department of Mechanical Engineering

Mechanical Engineering is a discipline of Engineering that is concerned with the working, design and Manufacturing of heavy tools and machines. It implies the principles of Science and Mathematics for analysis, design, manufacturing, and maintenance of mechanical systems. Students are introduced to the Mathematical Science & Art of formulation, design, development and control of systems, with components concerning Thermodynamics, Mechanics, Fluid Mechanics, mechanisms and energy conversion.

Students are continuously guided by faculty of national and international recognition, who are also members of prominent Engineering societies and counted among the outstanding scholars in their profession.

The Science of Mechanical Engineering emerged in the 19th Century as a result of developments in the field of physics. The field has continually progressed to cater the advancements in technology. Mechanical Engineering is today’s one of the most emerging field because of the upcoming new materials or composites, manufacturing methods, Mechatronics and Nanotechnology adoption.

At Global Group of Institutes, our expert and competent faculty are committed to the advancement of the fundamental Engineering Sciences to meet the current requirements of industry and Academics This is balanced by their demonstrated interest and active participation in practical developments as well.

Other than academics department is also running add on training programs on CNC Machining, Creo. 2.0 software, Advances in Manufacturing etc.

B.Tech @MED was accredited by NBA under TIER-2 program from 2016-19

| Degree | Duration | Seats |

|---|---|---|

| B.Tech | 4 years | 60 |

Department Vision

Emerge as a Center of Excellence in Mechanical Engineering through quality education, innovation and research.

Department Mission

Creating an excellent learning environment to foster globally competent Mechanical Engineers.

Imparting quality engineering knowledge by experienced and dedicated faculty, synergized with Industrial interactions and R & D activities.

Providing a vibrant environment to facilitate students’ professional and personal skills and values.

Program Educational Objectives (PEOs)

PEO1 Graduates shall have strong practical and theoretical expertise in Mechanical, allied engineering, mathematics and science and shall opt for employability or higher studies or research or entrepreneurship, either in India or abroad.\

PEO2Graduates shall have global outlook, technological leadership, creative thinking towards innovation and enterprise to contribute to society.

PEO3 Graduates shall have excellent teamwork, communication, interpersonal skills, high morals and ethical values.

Program Outcomes (POs)

PO1: Engineering Knowledge: Apply knowledge of mathematics, science, engineering fundamentals and an engineering specialization to the solution of complex engineering problems.

PO2: Problem Analysis: Identify, formulate, research literature and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences and engineering sciences.

PO3: Design/Development of Solutions: Design solutions for complex engineering problems and design system components or processes that meet specified needs with appropriate consideration for public health and safety, cultural, societal and environmental considerations.

PO4: Conduct Investigations of Complex Problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data and synthesis of information to provide valid conclusions.

PO5: Modern Tool Usage: Create, select and apply appropriate techniques, resources and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

PO6: The Engineer and Society: Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to professional engineering practice.

PO7: Environment and Sustainability: Understand the impact of professional engineering solutions in societal and environmental contexts and demonstrate knowledge of and need for sustainable development.

PO8: Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of engineering practice.

PO9: Individual and Team Work: Function effectively as an individual, and as a member or leader in diverse teams and in multi-disciplinary settings.

PO10: Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations and give and receive clear instructions.

PO11: Project Management and Finance: Demonstrate knowledge and understanding of engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

PO12: Life-long Learning: Recognize the need for and have the preparation and ability to engage in independent and life- long learning in the broadest context of technological change.

PROGRAM SPECIFIC OUTCOMES (PSOs)

PSO1: Capability to understand, identify, analyze, evaluate and form manufacturing systems using mechanical and allied engineering principles and techniques.

PSO2: Developing attitude among graduates to accept global challenges and apply mechanical engineering acquaintance for solving problems related to design, production and other interdisciplinary fields.

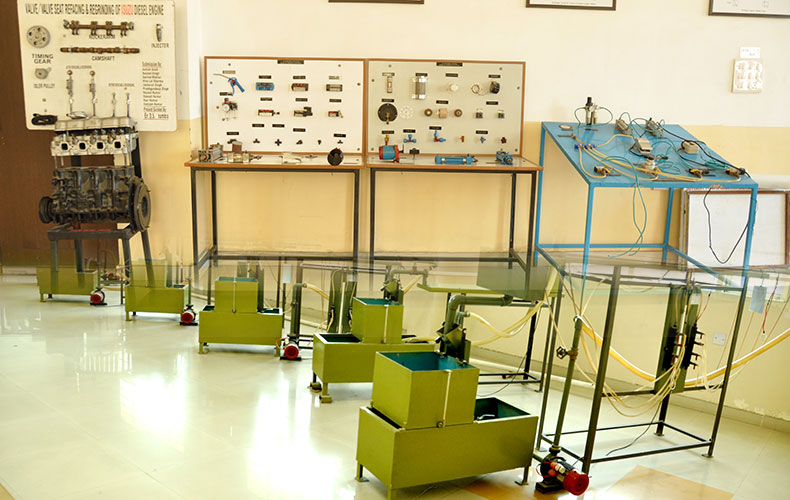

| S.no. | Labs |

| 1. | Manufacturing Practice |

| 2. | Engineering Computer Graphics |

| 3. | Engineering Materials & Metallurgy Lab |

| 4. | Strength of Materials lab. |

| 5. | Applied Thermodynamics Lab |

| 6. | Fluid Mechanics Lab |

| 7. | Manufacturing Processes Lab |

| 8. | Theory Of Machines Lab |

| 9. | Computer Aided Design And Manufacturing Lab |

| 10. | Mechanical Measurement and Metrology Lab. |

| 11. | Industrial Automation And Robotics Lab |

| 12. | Automobile Engineering Lab |

| 13. | Heat Transfer Lab |

| 14. | Fluid Machinery Lab |

| 15. | Refrigeration And Air Conditioning Lab |

| 16. | Mechanical Vibration Lab |

| 17. | Centre Of Excellence In High Performance Automobile |

| 18. | R & D Lab For Mechanical Engineering Department |

Latest Activities

“The Department of Civil Engineering and Mechanical Engineering organized A Road Safety Awareness Camp in collaboration with The NSS wing of the Global Group of Institutes on 5th February 2024”

Road safety sensitization is vital to ensure the safety of everyone. Making the general public aware of the importance of road safety can help reduce the rate of accidents and road mishaps that happen daily. Seminars and educating people can be helpful to guide them and make them aware of the consequences. To bring the same awareness to our students and the people around us, The Department of Civil Engineering and Mechanical Engineering organized A Road Safety Awareness Camp in collaboration with The NSS wing of the Global Group of Institutes on 5th February 2024 where students of our department took the initiative to interact with road users and made them aware of various Rules and Regulations regarding Road Safety including Mandatory Signs, Cautionary Signs, Informative Signs, Traffic Control Signals, Pedestrian Signals, Indian Highways Milestone Colour Codes, Road Markings as per Indian Road Congress etc. All the students participated in this initiative with full zeal and encouraged road users. The camp proved beneficial for students as they gained more knowledge in the field of Highway and Traffic Engineering through Practical Exposure.

“Department of Civil and Mechanical Engineering organized fun activity WORDS AND CIRCLE GAME for their students on 3rd March 2023.”

“Interdepartmental activity Technical Peek-A-Boo was organized by John Smeaton Club and Mechanical United Club in college campus on 17/2/2023.”

FUTURE OF AUTOMOTIVE INDUSTRY ELECTRIC VEHICLES IN INDIA ON 15-11-2021

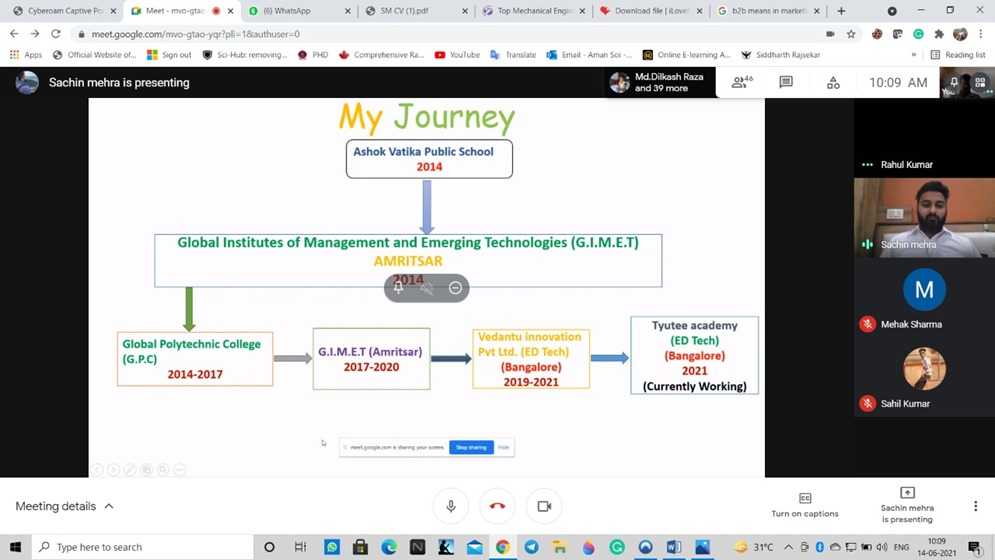

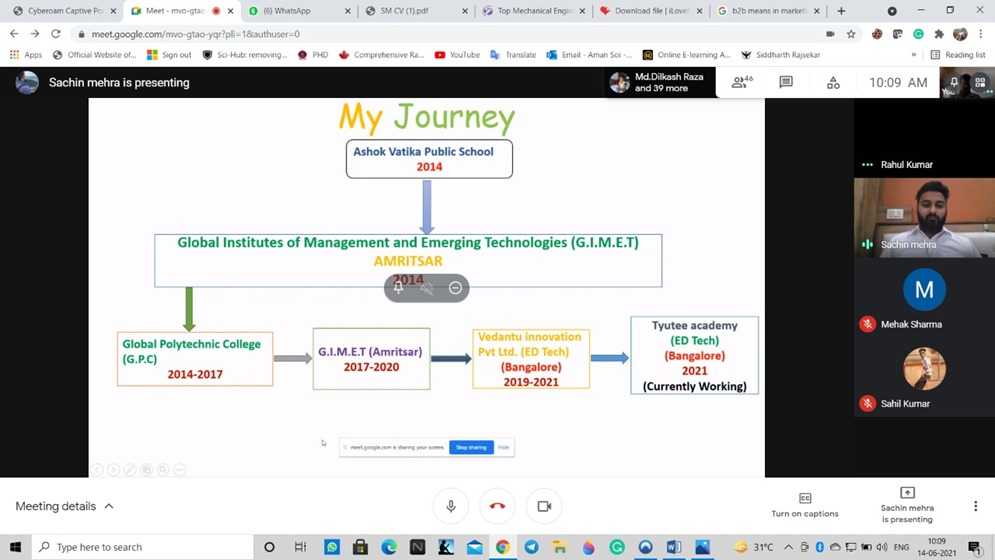

EDUCATION & TECHNOLOGY INDUSTRY ON 04-06 2021

National Seminar on Solidworks -An Industrial Prospective

Head of Department, Prof. DS Bhambra welcomed Er. Anurag Singh (Sr. Application Engineer), Idea Design Solution (Pvt). Ltd. Chandigarh. Er. Anurag Singh gave an insight view of Solidworks software and focused on the various application/module of solidworks like 3D-CAD, Virtual Solid State Analysis, Flow Simulation, Plastic Simulation, Sheet Metal Simulation with hands on training.

Guest Lecture On Working Of Thermal Power Plant

Industrial Visit At Rana Sugar Mill, Buttar, Amritsar

Guest Lecture on “GOOD RESUME & INTERVIEW SKILLS”

Guest Lecture on “Industrial Applications of Heat and Mass Transfer”

Mr. Negi has done his Master Degree in Steel Technology from IIT, Bombay. He has qualifiedthree times GATE exams with 99 percentile. Mr.Negi gave detailed Information on industrial applications of mode of heat transfer and fluid flow characteristics on different types of engineering applications i.e. Boilers, Turbine, Condenser, Generator and advanced technologies/software used in industry to evaluate the heat and mass transfer related problems.

Seminar on “Utilization of CNC Machines & Solid Works”

Guest Lecture on “Role of Psychrometry in Air Conditioning”

Workshop On Emerging Trends In CAD/CAM

Workshop On Digital Manufacturing Process (CNC M/C)

All Terain Vehicle Designed & Developed by Mechanical Engineering students

Fdp On “Sustainable Manufacturing and Operations Management

The Sorry State of Indian Engineers

One day seminar on “The Sorry State of Indian Engineers” was conducted by Mechanical Engineering Department on 19th March 2015 at conference hall. The seminar was attended by the students of 2nd year Mechanical Engineering and the favorable faculty.

Prf. DS Bhambra (Vice Principal) and Dean of Academics welcome the team of Techie’s Engineers headed by Mr. Anurag Byala (Managing Director). In his opening address, he brought out that the state of Indian engineers has changed from the Golden state of engineers (1970) to sorry state of engineers (2015). The various reasons for the same were also brought out and suggested the remedial measures. Mr. Anurag and his team explained to the students the topic through PPT presentation and video films. They stated that besides the regular academics, student must learn more on software packages and their applications in the modern industries.

The students attending the seminar appreciated the methods suggested to them and showed the path of better future of engineers in India.

SAE Activities

Students of the Department are actively involved in SAE (Society of Automotive Engineers) to Design & Fabricate Automotive Vehicles, F – 1 Cars with Highly Innovative Features.

Institute has adapted the policy to continuously encourage the students to undertake such projects and provide them with all the basic facilities to inculcate and acquire hands on practical training in the laboratories. Three groups of students have shown their Engineering Design Skills by successfully designing and fabricating an aesthetically attractive, fuel efficient aerodynamically shaped, vehicles based on the shape and design of F1 Formula Car. Pre-final and Final year Mechanical Engineering students took the challenge to take this project and have shown their acumen and design capabilities by developing the complete working model of the vehicle within the workshop resources available in the Institute using the 3-D AutoCAD software of CREO-2.0. The design and fabrication was done under the guidance of Faculty of Mechanical Engineering and Work shop Superintendent.

Following types of vehicle have already been designed & fabricated in the Department under aegis of SAE Society.

| 1. | Aerodynamic shaped vehicle with 800 CC Engine which can accelerate very quickly and has low weight to torque ratio & can achieve speed of 100 KMPH within 8 seconds. |

| 2. | Sports Car designed to meet the parameters of F1 vehicles, powered by 150 CC Engine, rear absorbers. Seats are ergonomically designed. Vehicle can beat the load of four passengers and can cruise at 80 KMPH in just 8 seconds. |

| 3. | 350 CC, 5000 rpm engine provide Torque of 1940 Nm. Total weight of vehicle including that of driver is 320 kg with a stopping distance of 5.54 meters. Vehicle can attain top speed of 60kmph. Innovation features of the vehicle include adjustable pedals, automatic light dipper, gear shift indicator. Also vehicle has a feature of not getting started unless driver wears the seat belt. |

Mechanical Engineering Department Guest Lecture on Career of Mechanical Engineering Students in India and Abroad by Er. Tejinder Singh Aulakh, Sr. Mechanical Design Engineer at Intel USA.

SAE Activities

Mechanical Engineering Department of Global Institutes organized a Guest Lecture on CAD CAM subject on 11th Sep 2013. The main topic was Modern Techniques of CAD CAM being used in our country and at International Level.

The Guest Lecture was delivered by Mr. Dharmendra, Manager, Technical Marketing Support from CADD Centre of Chennai. The lecture was attended by the Faculty Members and the students of 3rd year ME Deptt. Mr. Dharmendra gave live demonstration of all the commands being used, how to form the difficult figures and finally, how the assembly is being done using the latest package of Solid Works.

Students and the Faculty members attending the session appreciated the use of CAD CAM in the future industry and showed keen interest to follow it up further. The session came to an end by having get-together with all members attending the session. Mr. Dharmendra also appreciated the role being played by the department and the infrastructure built by the college.

One day Workshop on Modern Technologies adopted in Automobile Industries

A workshop on Modern Technologies adopted in Automobile Industries was conducted on 07th Mar 2013 in the college. Approximately 50 students from 3rd year Mechanical attended the workshop. The main concentration was on the CRDi system of diesel engines. Workshop covered the detailed components of the system, operation and function of each. The effect of varying parameters in form of inputs was also shown by conducting the practicals on simulators. The external Lap Top was attached who had all the input parameters through its software. The effect on the engine was shown to the students, with the variation on each parameters. The students were also given demonstration